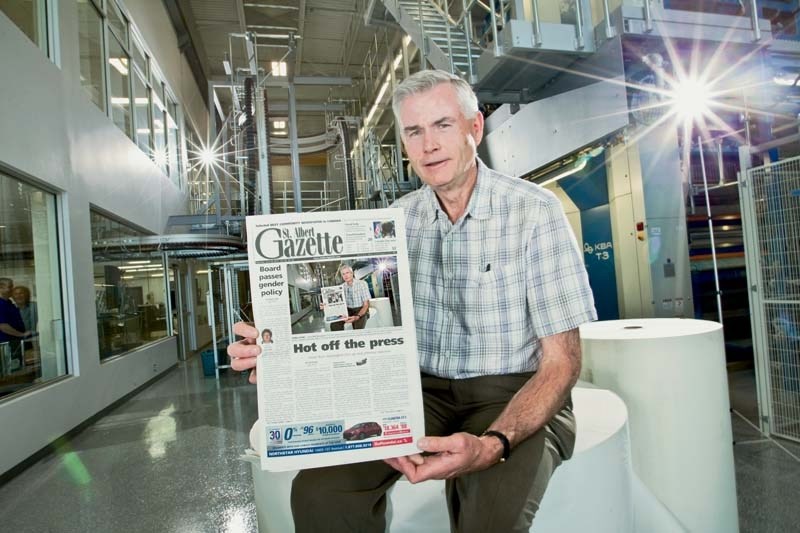

If you're reading this paper, it means the Gazette's new multimillion-dollar printing machine is up and running.

The Gazette's parent company, Great West Newspapers, threw the switch on its new Carleton Drive printing press Friday to print this edition of the St. Albert Gazette, the first commercial product made by the new machinery.

It's the end of a seven-year journey, one that's involved every person in the Great West chain, said CEO Duff Jamison.

"It's the biggest thing we've ever done," he said.

Manufactured last year in Germany, the new press came to St. Albert last December by ship and truck through Vancouver and the Panama Canal. Crews spent months before that pouring the five-foot-thick concrete slab needed to support it and keep its parts in alignment.

Crews used a huge crane and a rail-mounted hydraulic lift system to place the massive parts. Fully assembled this spring, the big blue machine stands three-storeys tall, weighs 356 tonnes – equivalent to 59 African elephants – and prints about 80,000 newspapers an hour.

View video of press assembly and newspaper production

Crews have zipped through about 40 tonnes of newsprint in recent months doing test runs to train on the new press, said plant manager Evan Jamison.

"There are so many components in the press that have to move," he said, and the software to control them is very complex. Press operators have spent many weeks learning the ins and outs of the new system.

And it's all highly automated. Print jobs that would take 20 people on the old Chisholm Avenue press will be done with as little as four on the new one, Duff said.

"We could, in fact, run it with one person," he said.

The automation also cuts back on paper waste. The old press wasted 15 per cent of its print runs because technicians had to make adjustments by climbing around with wrenches. The new one uses computers, servos and cameras to make split-second, on-the-fly adjustments to the press. This should cut paper waste down to about three per cent, Duff said.

The old press needed two print runs – one colour, one black and white – to produce the Gazette but the new one can print the whole paper at once.

"Jobs that might have taken five to six hours to print, we're now going to do in two hours," Evan said.

The new press is roughly three times as fast as the old one and has four times the capacity.

While this will allow Great West to print more papers, Evan said, it won't get those papers to your door any faster – most paper carriers are students, and the new press has no effect on dismissal times.

"The paper will be ready a bit earlier, but delivery times will remain more or less what they are," he said.

New dimensions

The Gazette itself has also changed due to the new press: it's now 41 by 27 centimetres big instead of 43 by 29.

"The big white margin that's been on the side of all the pages will disappear now," Duff said, reducing paper use by about seven per cent. Every page is also now in full colour.

The paper might be smaller, Duff continued, but it still has the same amount of content – crews are using a new layout process that fits ads and stories together more efficiently, cutting back on wasted space. Readers should also notice more interesting layouts – stories and photos that straddle two pages, for example.

Great West, which is a chain that includes 24 publications, plans to move other papers onto the new press in the coming months, Duff said. And under a contract secured in August of last year, Great West will begin printing the Edmonton Journal sometime this summer. Expect up to 60 delivery trucks to visit the Carleton Drive plant per day when that happens.

Next year the press will get an ultraviolet ink dryer that will produce more vibrant colours, allow printing on glossy paper and keep ink from rubbing off on your fingers, Duff said. The old press will be on standby as a backup until this fall, at which point it will be dismantled and sold.